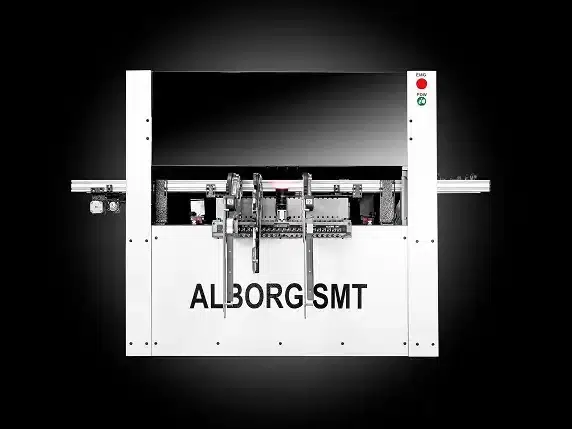

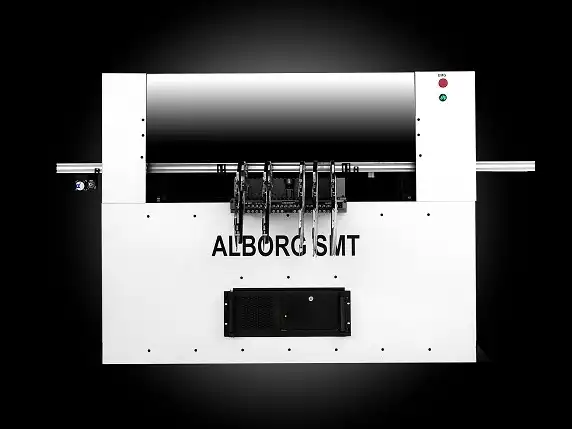

SMD Assembly Machine with Four Belt-Driven Heads

The desktop SMD assembly machine (Pick & Place Machine) offers excellent value for money considering its functionality and quality, making it one of the most popular products of this company.

The SMD assembly machine by Alborg comes with an outstanding software package, designed to be both user-friendly and comprehensive, offering powerful capabilities.

The seamless integration between this software and the SMD assembly machine enhances accessibility and functionality for operators, planners, and engineers. It also simplifies the management of component inventory significantly. The machine's operational data is continuously updated, which greatly aids in optimizing device management and ensuring smooth operation.

SMD Component Assembly Machine or Pick and Place Machine

The SMD board assembly machine features a fully user-friendly software with easy access and customizable permissions. Even regular users with no specific technical knowledge can manage the machine efficiently through this software.

For high-volume assembly of components, it is recommended to use automated methods. With the advancement of science and technology, the capabilities of these machines are constantly improving.

The head system in the SMD component assembly machine is capable of 360-degree rotation, enabling it to handle a wide range of components with varying angles effectively.

Industrial SMD Assembly Machine with Four Heads

The SMD assembly machine is a controllable device designed for assembling SMD electronic boards. Pick & Place assembly machines have revolutionized the electronics industry, as SMD technology has largely replaced traditional DIP assembly and has become widespread.

SMD assembly is progressively moving toward becoming smarter and fully automated. These machines are evolving into systems where a circuit board is fed into one side, and the output is a fully assembled SMD board ready for use.

This machine is highly suitable for prototype makers, enthusiasts, developers, and small-scale production teams, offering a perfect solution for efficient assembly.

With the advancement of technology and the replacement of DIP components with SMD ones, SMD assembly has become one of the most critical steps in the production of electronic boards.

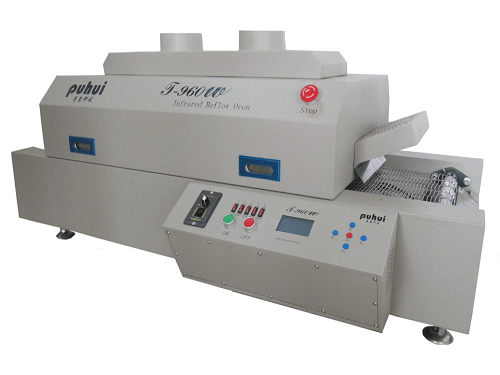

Industrial Oven Model T960

The T960 industrial oven is an advanced and efficient device in the field of assembly and production of electronic products. With its modern design and advanced features, this oven is widely used in the assembly of printed circuit boards (PCB). Its precise performance and uniform heating system make it an ideal choice for soldering sensitive and complex boards.

Thanks to features such as high precision, uniform heat distribution, and ease of use, the T960 industrial oven is a perfect option for companies and workshops seeking a reliable and cost-effective solution for assembling and soldering electronic boards. This device combines modern technology with versatile capabilities, meeting the diverse needs of the electronics industry.

Toaster Oven

The toaster oven, commonly known as a kitchen appliance, also finds a unique application in the electronics industry. Due to its compact size, adjustable temperature settings, and reliable performance, it serves as a practical tool for melting solder paste and soldering electronic boards. This method is particularly popular in small workshops and DIY projects.

Despite its initial design for household use, the toaster oven has proven to be a cost-effective and functional tool in the electronics industry, especially for soldering SMD boards and melting solder paste. Its affordability and simplicity make it an ideal solution for small workshops and beginners looking to carry out quality electronic projects.

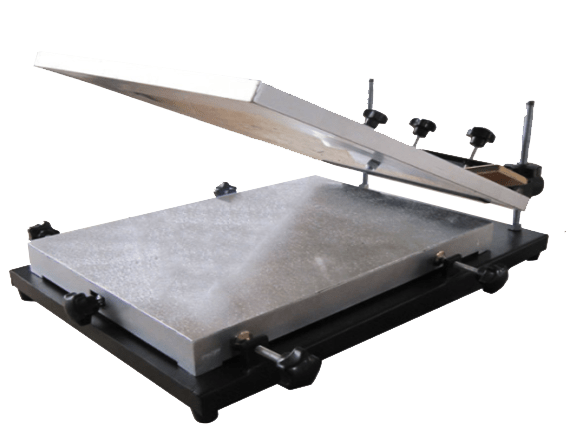

Manual Solder Paste Printer

The manual solder paste printer is one of the essential and widely-used devices in the process of assembling electronic boards. It allows for the precise application of solder paste onto specified points of the board. Due to its ease of use, high accuracy, and low cost, it is an ideal choice for small workshops, DIY projects, and low-volume productions.

With its simple design, precise performance, and affordability, the manual solder paste printer is an indispensable tool in the electronic board assembly process. It helps small workshops and low-volume manufacturers apply solder paste with minimal cost and maximum accuracy, significantly improving the quality of their production.

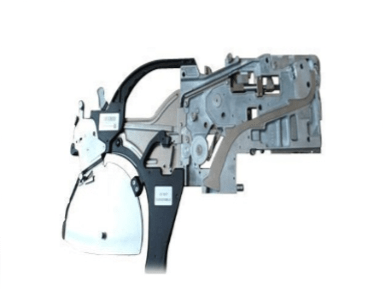

Feeder

The feeder is one of the essential and critical components in automatic assembly machines for electronic parts. It is used to supply electronic components to automated assembly machines (such as SMT machines) and plays a fundamental role in ensuring precision and speed in the production of electronic circuit boards.

The Samsung SM 8*4mm feeder is a highly practical and essential tool in the electronic component assembly industry. It enables manufacturers to optimize their production process using advanced technology. With its high quality and reliable performance, this feeder is an excellent choice for advanced production lines and industrial workshops.

Nozzle: An Essential Component in SMT Assembly Machines

The nozzle is a critical component in Surface Mount Technology (SMT) assembly machines, responsible for precisely picking and placing electronic components on circuit boards. Designed to handle a wide range of component sizes and shapes, nozzles play a vital role in ensuring accuracy and efficiency in the assembly process. They are typically made from durable materials such as stainless steel or ceramics to withstand wear and tear during high-speed operations.

Samsung nozzles, such as CN040, CN065, CN100, and CN140, are widely used in SMT machines due to their precision and compatibility with various component sizes. Each nozzle model is specifically designed for components with specific dimensions, ensuring a secure grip and accurate placement. The diversity of sizes and designs allows manufacturers to handle components ranging from tiny resistors to larger connectors, making Samsung nozzles an essential part of modern SMT assembly lines.

GAMA 4 Head

Gamma's industrial four-head SMD assembly machine is one of the best options for producing electronic boards with high precision and speed. This device, using advanced technology, provides the possibility of assembling all kinds of SMD parts on PCB boards. Four powerful and simultaneous heads of this device increase productivity and reduce production time.

Gamma's industrial four-head SMD assembly machine is one of the best options for producing electronic boards with high precision and speed. This device, using advanced technology, provides the possibility of assembling all kinds of SMD parts on PCB boards. Four powerful and simultaneous heads of this device increase productivity and reduce production time. Features such as high speed in SMD assembly, extreme accuracy, compatibility with all types of boards and affordable cost of production have made this device an ideal choice for electronic industries and professional manufacturers. If you are looking to sell an SMD assembly machine or upgrade your production line, our four-head industrial machines are a reliable and advanced solution.

Oven B630T

Automatic printer

- Use a proper accurate positioning servo system. -SPG uses imported linear guide and imported South Korean frequency conversion motor to drive the scraper, ensuring printing accuracy. -Printed scraper can rotate 45 degrees fixed upwards, cleaning and replacing the print scraper. - The scraper holder before and after adjustment is printed to select the appropriate position. - The combined printing plate taken has fixed groove and pin, easy installation and adjustment, suitable for single and double panel printing. -Way to finish the school edition using the stencil, and with the printing (PCB) X, Y, Z. Accurate and fast adjustment correction. - Use a 4.3-inch SamDraw real color touch screen + PLC human-machine interface control, simple, convenient and suitable for human-machine dialogue. - It can set different ways of one-sided and two-sided printing. - With automatic counting function, it is convenient to produce statistics. - The angle of the blade is adjustable, the steel blade, the rubber blade is suitable. - Protect the service life of the human machine interface by using the screen saver function. -Adopt unique program design, comfortable adjustment lyre printing. - Press speed screen interface, can be customized digital control setting.