Learn more about our devices

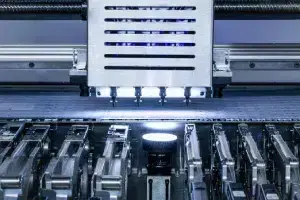

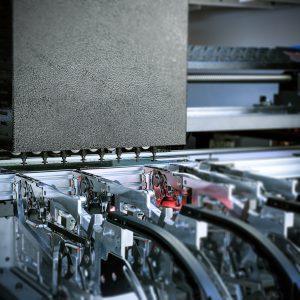

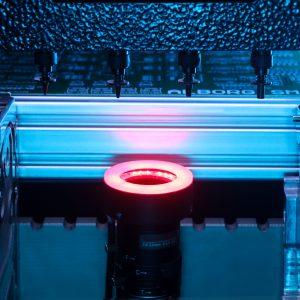

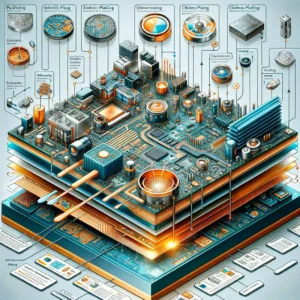

In today's world, in every device and tool that we use in our daily life, there is an advanced technology that enables unparalleled performance. While the old mechanisms were manual and heavy, today we are faced with SMD assembly machines and advanced robots that are light, precise and fully automated. These changes in technology, especially in production processes, not only increase productivity, but also improve accuracy and speed of operation. In the design and production of these products, beauty, efficiency and practicality are of great importance along with robotics and automation technologies. The technologies used must have features such as reliability, flexibility, power, productivity and economy in order to respond to the changing needs of the industry and improve production processes effectively and efficiently.

We listen carefully to the needs and demands of our customers and along with them, we create advanced technologies and efficient solutions that are the beating heart of modern technology that meets the needs of the electronics industry in a safe, accurate and efficient way. Our SMD assembly machines are designed and built with the goal of reducing production costs, increasing productivity and improving the quality of your products. Our solutions help you stay ahead in today's competitive market by strictly meeting technical specifications and improving product performance. Join us and benefit from the most innovative, reliable and economical technologies in your production process.

Features that distinguish us from others

Ability to assemble most parts

Focus on customers

Competitive price

Fifteen years of experience

Committed to time

Always available

by-products

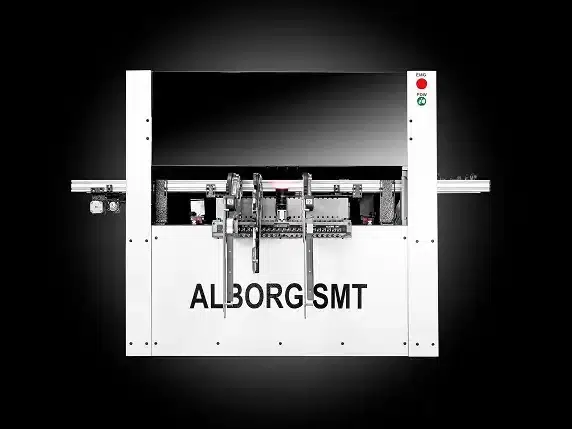

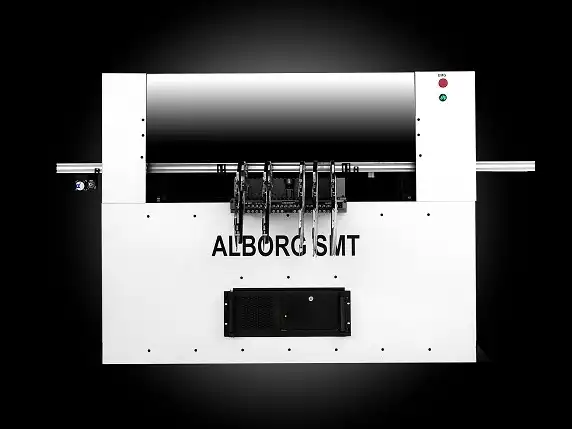

Use convenient accurate positioning servo system. Taken the SPG adopts imported linear guide and South Korea imported frequency conversion motor

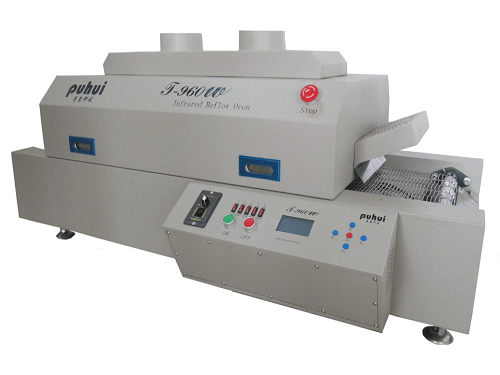

Toaster Oven An oven is used to melt tin paste. One of the most common ovens in the electronics industry