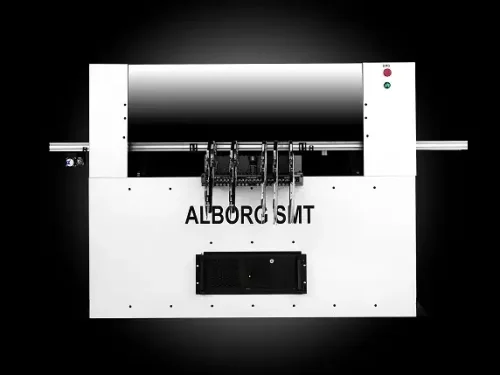

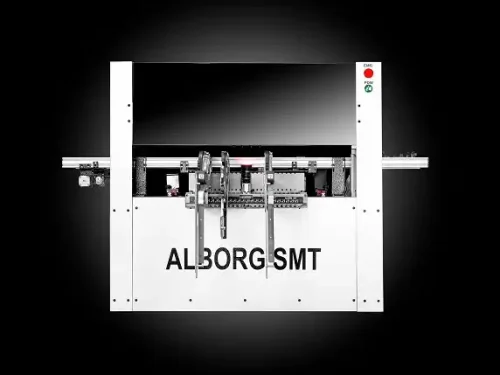

Industrial four-head SMD assembly machine

Extremely easy machine programming and file input from PROTEL software and various electronic design software

Easy operator-machine interface (one-day training)

Offline programming capability

Apply minor work changes online during operation with direct operator command

Internet installation capability for remote repair

SMD assembly machine or Pick and Place machine

SMD assembly machine is a controllable machine that is capable of assembling SMD electronic boards.

Today, SMD assembly technology

has generally replaced DIP assembly and has become widespread.

SMD assembly

is gradually becoming intelligent and fully automated, turning into a machine

that is given a circuit board on one side, and the output of the SMD assembly board is ready to use.

This device is very suitable for prototype makers,

enthusiasts, developers, and small batch development and production groups.

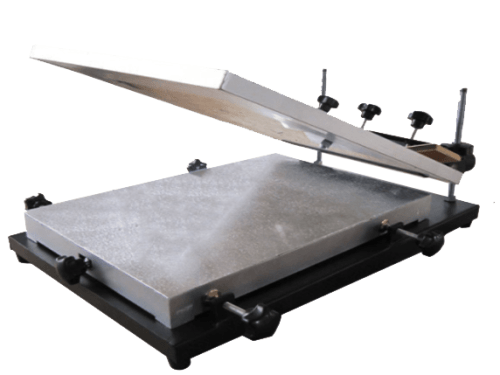

With the advancement of technology and the replacement

of SMD components with DIP components, one of the most important

production stages is now the assembly of electronic components on the board.

SMT component placement systems

or surface mount technology, are called pick and place machines.

These machines are robotic machines that are used to place

SMD components on printed circuit boards.

These devices are used to assemble a wide range of electronic components

such as capacitors, resistors, ICs, etc. on printed circuit boards with high precision and speed,

which can lead to the manufacture of computers and electronic equipment in various industries

including medical, automation, automotive, military and telecommunications industries, etc.

Assembly devices today play an important role in the production of electronic products,

and obtaining their manufacturing technology greatly helps the manufacturing sectors, and

Pishgam Trayab has designed and used this device

to reduce part of its production costs and make the cost price of its product competitive.

The hardware and software of these products are manufactured by Alborz Mechatronics Engineering Company in the Middle East

and no similar foreign product has been copied;

As a result, these products are usually supplied to the customer with the hardware specifications visible in the photos and videos

; however, according to the customer’s needs, changes

in SMD assembly hardware are possible

Extremely easy machine programming and file input from PROTEL software and various electronic design software

Easy operator-machine interface (one-day training)

Upgradability of the device in terms of hardware and software

Features

Reviews

There are no reviews yet.