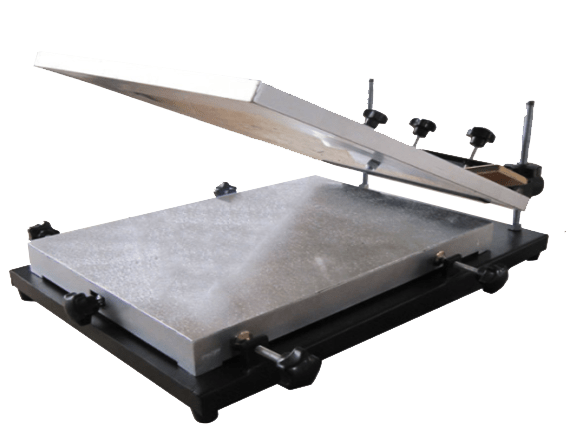

Tin paste manual printer

Handheld Tin Paste Printer

A handheld printer is an easy way to apply tin paste to electronic boards.

The operation of a handheld tin paste printer is a critical process and the machine must be carefully adjusted.

The settings of the handheld tin paste printer are completely manual.

Screw clamps are used to move the platform in the X and Y directions.

Stencils of different sizes are also secured to the upper frame using screw clamps.

Instruction

1) Place the precision printing table horizontally on the worktable to clean the oil, impurities and solder paste remaining on the steel mesh; after cleaning the steel mesh, place it on the screen clamp (2) , and adjust the five-star embossing knob ( 3) Move the steel mesh to a suitable position, and turn the five-star embossing knob to compress the steel mesh.

2) Install the PCB positioning block ( 11 ) and the PCB fixing seat ( 5 ) , adjust the position of the PCB fixing seat according to the distance of the PCB positioning hole and the position of the steel mesh and fix it (if the PCB board is large, the supporting column (9) ) Support, the support column should be screwed in with the corresponding threaded hole).

3) Rotate the up and down adjustment handle ( 1 ) to adjust the height of the screen clamp. Rotate X- axis rotary handle (6) and Y- axis rotary handle (7)Adjust the relative position of the PCB board and the steel mesh (if the relative position cannot be adjusted within the full stroke, please move the position of the steel mesh). If there is an angle difference between the relative position of the PCB board and the steel mesh, you should adjust the rotation adjustment handle (8 ) Make corrections; adjust the height of the bolts on the top column of the operating platform support base block ( 10 ) so that the four corners of the operating platform ( 4 ) are uniformly stressed without shaking.

4) Choose a scraper with no defect on the blade surface for tin scraping. The squeegee angle between the squeegee and the steel mesh should be between 30 degrees and 75 degrees (at the same squeegee speed, the squeegee angle of 60 degrees is larger than the squeegee angle of 75 degrees). In the operation, try to keep the scraping angle at 45 degrees and keep the scraping speed consistent.

5) After the stencil is used, the remaining solder paste should be cleaned up to keep the surface of the stencil clean for the next use.

1 review for Tin paste manual printer

Show only reviews in English (0)

آرمیتا –

سلام عالی بود

خرید کولر پنجره ای

eli aghdam –

ممنونم از نگاه زیباتون